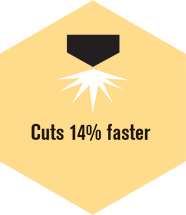

Productivity

Just like you measure a car’s efficiency by the miles it can drive on a gallon of gas, we measure the speed our machines can cut a given thickness, and the energy needed to do so.

The XPR™ cuts 3/4" thick material at 105 inches per minute at a power efficiency of 90%, compared to its predecessor’s speed of 90 inches per minute and 90% efficiency. This translates to an 4.4% increase in the inches2 it can cut per kwh, or in2/kwh.

The XPR consumables use less copper and have a longer life than their predecessors. To do the same amount of work, XPR consumables use 64% less copper and other materials.

The XPR boasts a more robust and reliable coolant pump. While is adds cost and weight initially, over the life of the system costs are reduced for the user and uptime is increased. Environmental impact is reduced because hundreds of pounds of resources are not put into replacement pumps and their shipment.

Energy efficiency

A car’s performance may also be measured with how fast it gets you where you want to go. We measure a plasma system in much the same way. A Hypertherm XPR will cut what you want, 14% faster than its predecessor.

The XPR delivers more power with fewer resources. Just like you want your car to have steel in the right places, and aluminum in others, so that it’s not too heavy, we want our XPR to use less resources to make. As measured in watts delivered / pound of weight, it is 62% more powerful than its predecessor.

Environment

Magnetic components are 77% more materially efficient as measured in watts delivered/lb, compared to their predecessors.

Packaging is 100% recyclable. Corrugated parts are more ergonomic to unpack and repack. Pallet is all wood and reusable or recyclable.

End users should consider repair and upgrade to extend the life of their system. At the end of its first life, a system should be sold on the secondary market, or used for parts. At its true end of life, it is 99.5% recyclable.

Learn more about what to do with your used Hypertherm products

Better markings on components will help insure that recyclable materials end up in the right place. All fasteners used are common and non-proprietary, so disassembly, repair, and recycling are easier.